Get The Rapid Results You Need With Our Odessa Rebabbiting Service

Every minute that your equipment is down equals money lost. For oilfields, even seconds can mean tens of thousands of dollars stripped off of bottom lines. The good news is that you don’t have to deal with equipment-related delays for long. You can get things back up and running with our Odessa rebabbiting service. Read on to find out how ACO Machine and Tool, LLC can fix your oilfield pump bearings fast.

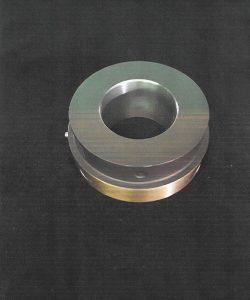

Our rebabbiting service relines bearings. It takes far less time than bearing replacements. It’s also far less disruptive and costs a lot less money. This process replaces worn babbit linings with fresh, unblemished material. This technique works well on many different equipment types. Although we regularly provide it for oilfield pump bearings, it’s also frequently used on turbines, compressors, and many marine vessels.

Babbiting or rebabbiting isn’t just a repair service. It’s also something that we do for our clients as a preventative measure. This is a great way to extend the lifespan of your drilling equipment by minimizing friction, health, and other wear-causing factors. Best of all, with our help, these treatments can also boost the efficiency and overall performance of your tools.

You can count on us for excellent prices and rapid arrival times. We know that our clients are heavily reliant upon their drilling tools and other machinery. We maintain an expansive team of highly trained technicians. We dispatch team members in fully stocked trucks so that they’re prepared to meet the demands of every job.

You may need oil and gas compressor repair if your equipment is suddenly making strong vibrating movements and issuing louder-than-normal sounds. Burnt odors, poor performance, and loud, grinding or shrieking noises are also signs of problems. If you have these or any other concerns, give us a call now. We’ll send a team out to determine the perfect solution. In addition to rebabbiting, we also provide new bushings and bronze babbit bearings.

Rebabbiting is a process that restores worn or damaged bearings by replacing the babbit lining with new babbit material. The process can be used on a variety of machinery, including marine engines, compressors, turbines, and cement plants. Rebabbiting can extend the life of machinery, improve its performance and efficiency, and reduce the need for costly replacements.