What Are The Steps Involved In Oil And Gas Compressor Repair?

Oil and gas compressors are crucial pieces of machinery that help boost pressure in pipelines to efficiently transport product. However, with constant use, compressor parts can wear down over time. Learning the standard steps of an oil and gas compressor repair process can help operators properly maintain these vital assets.

Inspecting for Wear

The first stage of any compressor repair is a thorough inspection. Carefully examine parts that see heavy usage like pistons, rings, bearings, gears and seals. Pay close attention to clearance measurements and look for signs of corrosion or abrasion. Documenting wear and clearances is crucial for determining the necessary repairs.

Disassembling Components

Once inspection is complete, it’s time to disassemble the compressors. Carefully break down components according to manufacture specifications. Keep fasteners and small parts organized to ensure proper reassembly. Components like cylinders may need to be removed from the overall frame for easier access.

Cleaning and Inspection

Thoroughly clean and inspect each part individually. Flush passageways and check for any remaining debris or contaminants. Re-measure clearances and dimensions to confirm the extent of any wear. Inspect parts under magnification as needed to detect small defects. Our experts will always document inspection findings to determine the full scope of repairs.

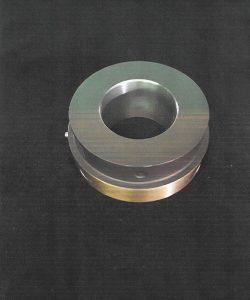

Repair or Replace Parts

Based on inspection results, you may be able to restore worn parts through methods like honing cylinders or resurfacing mating components within allowed tolerances. Otherwise, replacement is necessary. Consult with an experienced oilfield parts and equipment supplier to source OEM-quality Oil and Gas Pump Parts for worn pistons, rings, bearings and seals.

Reassembling the System

Carefully reassemble the compressor using assembly lubricants as needed. Pay close attention to clearances and torque specifications during reassembly. Check for proper operation and leak test before returning the compressors to service. Conduct run tests under low-pressure conditions to ensure smooth functionality.

Maintenance Moving Forward

To prevent repeated repairs, implement a comprehensive preventative maintenance program. Inspect components regularly for wear and replace parts proactively. Work with an oilfield parts and equipment supplier that offers turnkey solutions from inspections to maintenance plans. This can help optimize compressors performance over the long run.

Here at ACO Machine & Tool Inc, we can assist with all your compressor repair needs. As an experienced oilfield parts and equipment supplier, we offer OEM-quality replacement bearings, bushings, pistons and more. Contact us today to request a quote on parts or to schedule an equipment inspection.